Nos engagements

TUBULAIRE D’ÉLEVAGE FABRIQUÉ EN FRANCE

Parce que notre exigence nous pousse à faire davantage que ce que la législation prévoit, nous avons créé notre propre label, porteur de notre engagement :

Nous garantissons une fabrication française avec une maîtrise totale de la conception, de la fabrication, du contrôle qualité et de la logistique en interne.

Nous utilisons un acier à 95 % français. Nos tubes bénéficient du label Véritube, certifiant leur fabrication en France par Arcelor Mittal, dans leurs usines de Lexy (Meurthe-et-Moselle) et du Fresnoy-le-Grand (Aisne).

Nous faisons réaliser la galvanisation à chaud de nos tubulaires par notre partenaire ZINQ Val de Loire dont les ateliers sont installés au sein même de notre site de production depuis le début des années 80. Le procédé utilise un zinc de première qualité et sans plomb.

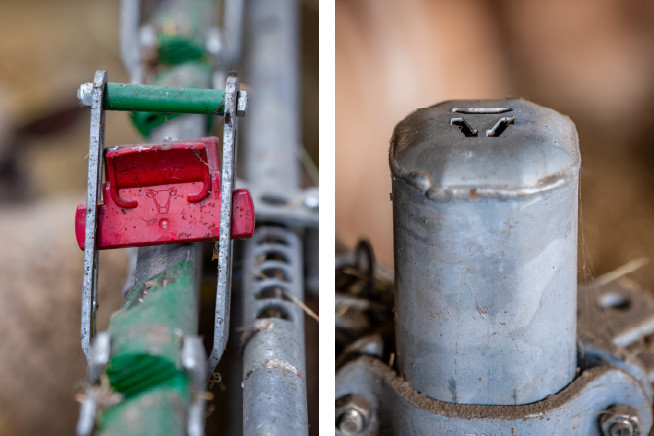

Comment reconnaître un produit JOURDAIN ?

Chez JOURDAIN, chaque produit reflète notre savoir-faire et notre engagement de qualité. Pour garantir l’authenticité, tous nos équipements portent un signe distinctif : la marque ou le logo JOURDAIN sont estampillés directement sur nos produits.

Ces détails, visibles et uniques, sont un véritable gage de fiabilité. Ils permettent de vous assurer que vous avez entre les mains un produit conçu pour durer, répondant aux standards élevés qui font notre renommée.

DÉMARCHE RSE JOURDAIN

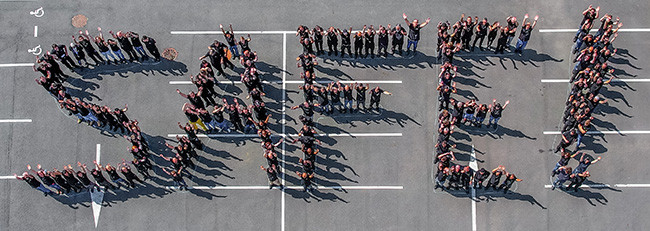

Les entreprises sont des acteurs importants dans la mise en place de pratiques plus respectueuses de l’humain et de l’environnement. JOURDAIN prend part à cet effort global en initiant des actions concrètes et en y impliquant l’ensemble des 220 collaborateurs. Notre but est de poursuivre notre croissance en ayant un impact positif sur la société.

Notre politique sociétale

De bonnes relations et conditions de travail sont primordiales pour que chacun de nos 220 collaborateurs s’épanouisse dans le cadre de son activité professionnelle.

Employeur majeur de notre territoire, nous contribuons à son dynamisme économique en offrant des perspectives d’emploi stable avec les avantages liés à notre taille.

JOURDAIN donne sa chance à toutes et tous en traitant chacun avec respect et bienveillance.

Le respect des bonnes pratiques en matière d’hygiène et de sécurité réduit les risques d’accidents et contribue à créer un environnement de travail sûr. JOURDAIN investit régulièrement dans des équipements en phase avec l’innovation technologique : découpe laser, plieuses tôle et grugeuses tubes en ligne automatique, qui réduisent la pénibilité pour nos équipes.

Les efforts soutenus en faveur de la formation et de la transmission de nos savoir-faire et de nos valeurs assurent la pérennité de l’entreprise et de la qualité des produits JOURDAIN. Parmi nos collaborateurs, nombreux sont ceux qui ont pu acquérir de nouvelles compétences et progresser au sein de l’entreprise.

Sur la base de la loyauté des pratiques et du respect de la parole donnée, JOURDAIN a bâti un réseau étendu de fournisseurs et de partenaires commerciaux.

Notre politique environnementale

Instaurer un cadre de travail productif tout en respectant au mieux l’environnement est l’un des points importants du développement de JOURDAIN, aujourd’hui et demain.

L’entreprise réduit son empreinte carbone à travers plusieurs actions :

Nous sommes équipés d’un parc complet de chariots élévateurs électriques sans émissions polluantes.

Dans un but de sobriété énergétique, nous utilisons des éclairages LED sur l’ensemble de nos sites.

Pour permettre un retraitement ou une valorisation, l’ensemble des déchets générés par notre activité est trié et recyclé.

Nous privilégions l’utilisation de lubrifiants à solution aqueuse à 95 %.

La galvanisation utilise un zinc sans plomb et est effectuée sur notre site de production, réduisant ainsi l’impact du transport routier.

Nous favorisons une sous-traitance sur le territoire français afin de réduire notre impact carbone.